The Progressive Dynamics of 3D Printing

A Conceptual Exploration of Algorithms, Materials, and Layer Architecture in Additive Manufacturing

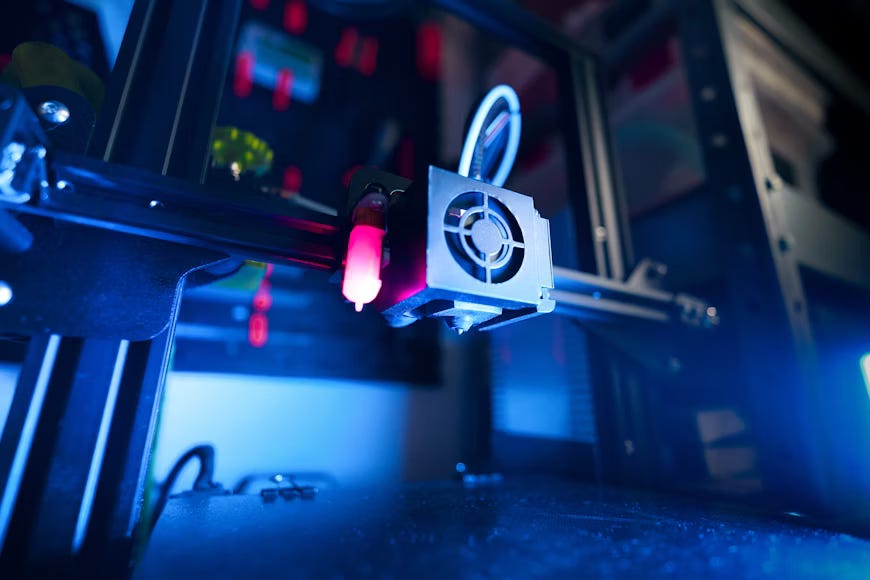

Introduction

Additive manufacturing (AM), widely known as 3D printing, has matured from a tool for rapid prototyping into a cornerstone of advanced manufacturing. Its capacity to produce highly complex geometries, reduce material waste, and allow on-demand fabrication has made it attractive to industries such as aerospace, medicine, and electronics. This transformation rests not on a single innovation but on the convergence of three core factors: advanced algorithms, material development, and architectural control of printed layers. This paper explores how these three components function in tandem to enhance precision, efficiency, and customization in AM—and why their integration matters for the future of production economies and technological innovation.

From Basic Slicing to Adaptive Algorithms

Early 3D printers depended on simple slicing software that turned CAD models into printable layers. While functional, this method limited design freedom and often required manual support structures. Today, advanced algorithms—many rooted in machine learning—can predict and correct errors in real time. Mahmood et al. (2020) discuss how artificial neural networks (ANNs) are now applied to predict melt-pool stability, reduce defects, and optimize toolpaths. Meanwhile, Liu et al. (2018) demonstrate how topology optimization enables designs that are both lightweight and structurally robust. These developments shift computational tools from passive translators to active decision-makers within the manufacturing loop.

Material Development and Application-Specific Functionality

Material science has expanded the range of printable substances from simple thermoplastics to metals, ceramics, and stimuli-responsive polymers. PLA and ABS remain common due to their affordability and ease of use, but emerging materials now support more advanced functions. For example, Bhatia and Sehgal (2023) describe biodegradable composites used in environmentally friendly applications, while Tetsuka and Shin (2020) document how bioinks with living cells are reshaping tissue engineering. In aerospace, metal powders like Ti-6Al-4V are used in powder bed fusion systems to fabricate lightweight components with high strength-to-weight ratios. These advances show how material innovation directly supports the shift toward high-performance, application-specific parts.

Layer Architecture as a Functional Design Tool

Layer-by-layer construction is not merely a constraint but a design variable. Changes in layer height, print orientation, and deposition path can influence mechanical properties, surface finish, and build time. As Ghilan et al. (2020) note, adaptive slicing methods now allow for finer resolution in complex regions while maintaining efficiency in simpler areas. CLIP (Continuous Liquid Interface Production), developed by Carbon Inc., has demonstrated how speed and resolution can be improved simultaneously through continuous printing rather than discrete layering. Architectural control extends further in applications like multi-axis printing and bioinspired designs, where internal geometries mimic structures such as bone or nacre for enhanced toughness (Leung et al. 2019).

Integrated Systems and Economic Implications

The most substantial improvements in AM arise from the integration of algorithmic intelligence, material properties, and controlled deposition. For example, General Electric has used topology optimization and DMLS (Direct Metal Laser Sintering) to consolidate over 20 parts of a jet engine nozzle into a single printed unit, reducing both weight and production steps. Such consolidation reduces assembly labor and potential failure points—directly impacting manufacturing costs and reliability. In the biomedical field, Ghilan et al. (2020) report on the use of custom bioprinted scaffolds tailored to individual patients, improving treatment outcomes and reducing hospital stays. These examples illustrate the broader economic benefits of AM, such as reduced supply chain complexity, minimized waste, and faster time to market.

Challenges and Opportunities

Despite progress, obstacles remain. Multi-material printing still faces issues with bonding and shrinkage mismatch at material interfaces (Bhatia and Sehgal, 2023). Process monitoring systems are often proprietary and lack interoperability. There is also a growing need for standardized data formats and quality assurance protocols to allow broader adoption in critical fields like healthcare and aerospace. Researchers such as Mostafaei et al. (2021) argue for the development of digital twins—virtual models of the printing process—to address these challenges by enabling simulation, prediction, and real-time correction before errors manifest physically.

Conclusion

The current wave of innovation in additive manufacturing is not the result of isolated breakthroughs, but of the steady integration of algorithms, materials, and architectural strategy. Each element plays a critical role: algorithms make real-time decisions, materials provide the functional base, and layer structures shape performance. Their combined effect is a manufacturing system that is more flexible, more precise, and more capable of meeting the demands of custom, sustainable production. As industries continue to digitize and decentralize, the strategic value of this integration will grow. Future research should prioritize open data standards, cross-disciplinary collaboration, and accessible monitoring tools to fully realize the benefits of this evolving technology.

Reference

Bhatia, A., & Sehgal, A. K. (2023). Additive manufacturing materials, methods and applications: A review. Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2021.04.379

Ghilan, A., Chiriac, A. P., Nita, L. E., Rusu, A. G., Neamtu, I., & Chiriac, V. M. (2020). Trends in 3D Printing Processes for Biomedical Field: Opportunities and Challenges. Journal of Polymers and the Environment. https://doi.org/10.1007/s10924-020-01722-x

Leung, Y. S., Kwok, T. H., Li, X., Yang, Y., Wang, C. C. L., & Chen, Y. (2019). Challenges and Status on Design and Computation for Emerging Additive Manufacturing Technologies. Journal of Computing and Information Science in Engineering. https://doi.org/10.1115/1.4041913

Liu, J., et al. (2018). Current and future trends in topology optimization for additive manufacturing. Structural and Multidisciplinary Optimization, 57(6), 2457–2473.

Mahmood, M. A., Visan, A. I., Ristoscu, C., & Mihailescu, I. N. (2020). Artificial Neural Network Algorithms for 3D Printing. Materials.

Mostafaei, A., et al. (2021). Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Progress in Materials Science, 119, 100795.

Tetsuka, H., & Shin, S. R. (2020). Materials and technical innovations in 3D printing in biomedical applications. Journal of Materials Chemistry B, 8(5), 961–977.